Tight buffered fibres are surrounded with a layer of aramid yarns as the strength member. Then a LSZH sheath is extruded. The strength member can be made of other high-strength yarns and other sheath materials are available on request.

Details

Specification

Documents

Details

Applications

Suitable for Military use, Outdoor

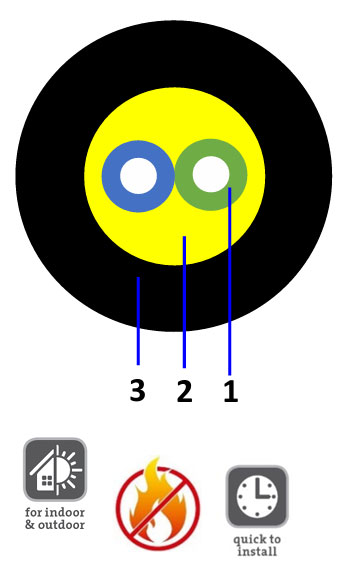

Cable Structure

- Tight buffer fibers

- Strength member

- Polyurethane jacket

Features

- All-dry design, easy for branching and splicing

- Small size and light weight, easy for installation

- Fast Field Termination: 900 µm tight buffered fibers make termination simpler

- Rugged Construction: Superior level of crush resistance and repeat-use resistance

Specification

| Fiber Count | Part Number | Nominal Outer Dia (HxW) in mm | Weight (kg/km) Approx. | Tensile Strength (N) | Crush Strength (N) | Min. Bend Radius Operation (mm) |

| 2 | PC-OFC-96-SM-01-002 | 5 | 30 | 1000 | 2000 | 50 |

| 4 | PC-OFC-96-SM-01-004 | 5 | 30 | 1000 | 2000 | 50 |

*Specifications are subjected to change without any prior notice

| Fiber Attributes | ||

| Fiber Name | Single Mode (G.652.D) | Single Mode (G.657.A1) |

| Wavelengths (nm) | 1310/1383/1550 | 1310/1550/1625 |

| Maximum Attenuation(dB/km) | 0.5/0.4/0.5 | 0.4/0.3/0.4 |

| Temperature Range | |

| Storage | -40 ⁰C to 70 ⁰C (-40 ⁰F to 158 ⁰F) |

| Installation | -10 ⁰C to 70 ⁰C (-14⁰F to 158 ⁰F) |

| Operating | -10 ⁰C to 70 ⁰C (-14 ⁰F to 158 ⁰F) |

Documents